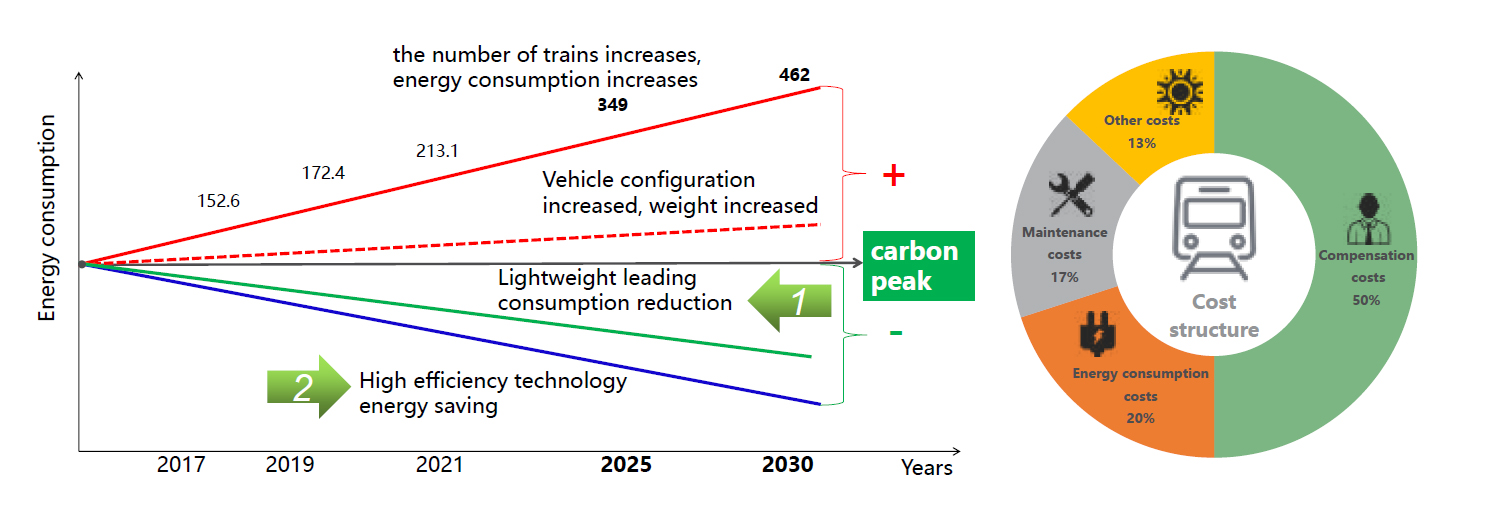

Rail transit vehicles as well as energy consumption is increasing year by year. Intelligent systems are increasing as well requiring the installation of obstacle detection, running gear monitoring, pantograph monitoring, automatic driving, passenger information system and other devices which determines a further increase in weight . This leads to an increase of energy consumption resulting therefore difficult to reach the carbon peak. In order to achieve carbon emissions reduction, the application of lightweight and high efficiency technology should be carried out.

Considering user costs, energy cost accounts for a large proportion and reduced energy consumption can bring other cost reductions; in addition most of the energy consumption related to motion resistance is closely related to the weight. In this context lightweight is of huge significance to reduce energy consumption and user cost

Bogie characteristics

• Lightweight

• Lightweight

Through comprehensive technical measures such as concept lightweight, Aluminum structure and innovative material, ARCO powered bogie is 5.8 tons, 25% less than traditional bogie and non-powered bogie is 3.7 tons, 35% less than traditional one.

• Safety

1) The leaf spring adopts multi-level stiffness design. Through this design the train has high safety features either when is empty or fully loaded.

2) The frame adopts flexible structure which can better adapt to lines with bad conditions while improving safety of train operation.

3) Sensors for monitoring temperature, vibration, load and dynamic performance are arranged for key components..

• High Efficiency

• High Efficiency

Permanent magnet direct drive traction motor is adopted:

1) Without gearbox and coupling, reducing the efficiency loss by 2.5%.

2) Compared with traditional traction system, the trans-mission efficiency of the permanent magnet traction system is improved by 2.5%.

3) The axle box bearing is used as motor bearing. 14 sets of bearings for driving device are saved for each bogie. The maintenance cost is low.

• Green

1) Green manufacturing: ARCO bogie adopts fully assembled welding-free structure, reduces the emission of welding smoke and dust in the manufacturing process and realize green environmental protection in the manufacturing process.

2) Green application: lightweight, high efficiency, reducing energy consumption and wear.

3) Green travel: wheel-rail forces and noise are reduced. Passengers’ comfortable and healthy travel experience is improved.

Test verification

ARCO bogie has been developed as a multi-platform product with different speeds and axle loads. At present ARCO bogie with 14t axle load and 160 km/h speed has completed six-level tests including verification of materials, components and the whole vehicle and has completed 5000 kms running in a metro line in China. ARCO bogie with 16t axle load and 200 km/h speed has been developed and designed and is being manufactured and tested.

Value to the customer

• Low energy consumption

Compared with the traditional bogie ARCO bogie, used on a simulated 200 km/h high-speed EMU, reduces the weight of the whole 8-car train by 32.7 tons and saves 16.37% of energy. Each train will save about 1,648,800 KW.h of electricity per year and considering the total life cycle (30 years) of each train can save nearly 49.5 billion KW.h

• Low wear

The use of inboard and small wheelbase can reduce wheel and rail wear.

On wheel it improves its service life, prolonging the cycle of wheel rotation repair.

On rail it reduces the cost of grinding equipment, prolonging grinding cycle and increasing line utilization.

• Low cost

Due to the use of permanent magnet direct drive motor each bogie:

saves 14 sets of bearings reducing maintenance costs

reduces 2000L gearbox oil consumption during the whole life cycle.

• Low noise

ARCO bogies reduce noise by 2-3 dBA, improve passenger comfort and reduce the impact on surrounding residents.

Share on: