As a technology company committed to meeting the world’s sustainability challenges head-on, Cummins’ mission is to power a greener, more prosperous world. We call this Destination Zero. Our broad portfolio of power solutions is innovative, dependable, and helps customers around the world improve their efficiency and environmental credentials.

Nowhere is this more apparent than in the rail industry.

Rail has a long history of underpinning economic growth. It transforms lives, businesses, and communities. It has the potential to support responsible consumption and a circular economy in the face of increasing urbanisation and population growth.

Rail reduces road congestion and carries more customers and more freight using less energy than most other modes of transport. It also produces fewer emissions. Cummins recognise the potential of developing increasingly sustainable, more resilient, and safer railways for everyone.

Our vision, experience, and technical expertise helps us to look beyond the obvious and bring critical thinking to all sustainability challenges.

Many companies are pursuing Alternative Power as a potential answer to the world’s climate goals, and Cummins is leading the charge in battery, fuel cell and hydrogen production technologies. In fact, we’re way ahead of the curve.

Many companies are pursuing Alternative Power as a potential answer to the world’s climate goals, and Cummins is leading the charge in battery, fuel cell and hydrogen production technologies. In fact, we’re way ahead of the curve.

Our fuel cells and hydrogen technologies have already powered applications ranging from grocery trucks to the first PEM electrolyzer in the United States, and now innovation continues to revolutionize passenger rail in Europe.

French railway manufacturer Alstom is among the first railway manufacturers in the world to develop hydrogen fuel cell-powered passenger trains using Cummins’ technology. The Coradia iLint™ entered commercial service in Germany in 2018; a zero-emission train emitting low levels of noise, the iLint™ is re-positioning possible through a combination of different innovative elements: clean energy conversion, flexible energy storage in batteries, and smart management of traction power and available energy.

Specifically designed for operation on non-electrified lines, it enables clean, sustainable train operation while ensuring high levels of performance. It’s the perfect illustration of Cummins’ commitment to designing and delivering innovative and environmentally friendly solutions.

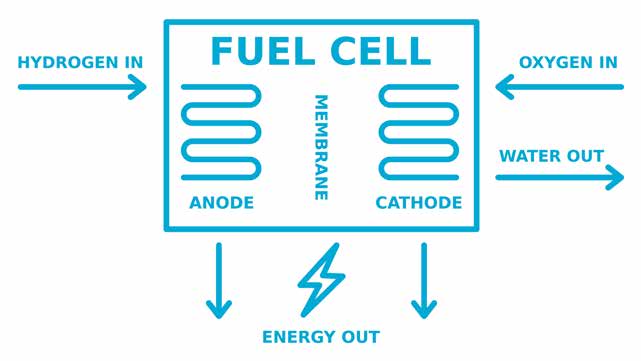

But what exactly is a hydrogen fuel cell and how does it work?

In simple terms, Hydrogen fuel cells produce electricity from a chemical reaction caused by combining hydrogen and oxygen atoms. This reaction causes the hydrogen to split into protons and electrons. The protons pass through the proton exchange membrane unimpeded and proceed to the cathode side, while the electrons are blocked and forced to travel through an external circuit. As they travel along the external circuit, they provide the electricity to drive a motor. Eventually the hydrogen protons and electrons reunite and combine with oxygen to produce water – the only emission produced by this technology.

And when hydrogen is generated from renewable electricity—like solar—wind, or hydropower—it is a completely decarbonized, renewable, fuel.

But there are many benefits to this technology besides the obvious environmental advantages. Not least the inherent efficiency and reliability when compared to the traditional combustion engine, due to having fewer moving parts.

But while technology such as hydrogen fuel cells are proving to be a viable path for a carbon-neutral future in a variety of mobile and stationary applications, our technological savvy and real-world experience tell us that for some operators are not ready to adopt leading technology. It doesn’t mean they’re any less environmen-tally committed, it just means they’re not there yet. There’s the remote operational nature of many machines to consider and the availability of resources within a specific region – not to mention the commitment and cost involved in modernizing their fleets and infrastructure. In fact, there are many social and economic factors why the transition to technologies such as hydrogen will be a gradual one.

And that’s fine. Wherever you are in your sustainability journey, Cummins has a clean, durable, low-carbon solution to drive you forward on your journey to Destination Zero.

In the short term, there’s plenty we can do, and plenty that we’re already doing. For example, clean diesel technology is part of Cummins’ broad portfolio of products right now and results in a highly efficient, virtually smoke-free engine, which can significantly lower greenhouse gases with Tier 4 and Stage 5 engines. Cummins engines are also capable of running on alternative fuels, such as HVO which can lower your carbon footprint with no immediate change to fleets and infrastructure.

In addition to alternative fuels, innovative data analytics and reporting has an important role to play in optimizing the performance of equipment and reducing emissions. PrevenTech® is Cummins’ newest remote engine monitoring and reporting solution. By combining engine hardware, digital technologies, and data-driven expert analysis, PrevenTech® delivers proactive recommendations that allow customers to increase equipment availability, improve safety and reliability, and enhance operational efficiency.

The journey we’re on is a first-class ticket to a better and brighter future for all. And as the rail industry blazes a trail towards Destination Zero, Cummins will continue to drive innovation – helping customers meet their short-term sustainability goals and stay on track towards those longer-term decarbonization aspirations.

Find out how Cummins can get you to Destination Zero at https://www.cummins.com/company/esg/environment/destination-zero

Share on: